Occupational Safety

Hess emphasizes a culture of ownership for occupational safety by empowering workers and giving them the responsibility to identify and mitigate the potential safety risk relevant to their operations.

Hess emphasizes a culture of ownership for occupational safety by empowering workers and giving them the responsibility to identify and mitigate the potential safety risk relevant to their operations.

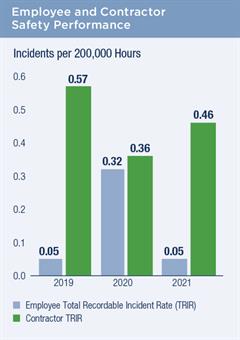

In 2021, we achieved a 9% reduction in our workforce total recordable incident rate (TRIR) compared with 2020, just under our goal of a 10% reduction year over year. This reduction was driven by a year over year decrease in our employee TRIR but was offset by a slight increase in our contractor rate – due to one additional contractor safety incident compared with 2020. Our workforce lost time incident rate increased from 0.09 in 2020 to 0.12 in 2021, again due to one additional lost time incident compared with 2020. No employee or contractor fatalities occurred during 2021.

In response to incidents throughout the year, our asset teams conducted root cause analyses and implemented corrective actions across our onshore and offshore operations. We share information on safety incidents and related lessons learned across our operations to help prevent future incidents.

Hess’ enterprisewide annual incentive plan metrics include a target aimed at reducing the rate of severe and significant safety incidents (SSSIs). In 2021, our SSSI rate was 0.420 – a six year low and a 14% reduction from 2020 – which surpassed our target of 0.423.

As part of our SSSI rate, we track near miss incidents that have the potential to result in severe consequences, as well as incidents that result in an actual consequence, including Tier 2 process safety events (PSEs) and recordable incidents. We require that near miss incidents be reported internally and recorded into our incident management system as if an actual consequence had occurred.

Process Safety

The aim of Hess’ process safety program is to prevent the unplanned or uncontrolled loss of primary containment of any material, including materials that are nontoxic and nonflammable (e.g., steam, nitrogen, compressed air), that could result in an incident such as an injury, fire, explosion, toxic release or environmental impact.

We focus on understanding and identifying key points within process safety systems that could impact asset integrity and the safe and proper operation of equipment. In particular, we address:

- Design integrity: reducing risks in the design and construction of facilities

- Technical integrity: inspecting, testing and maintaining hardware and software barriers

- Operational integrity: working within operational design parameters

Our approach to process safety involves identifying, managing and mitigating risks across Hess operations. We do this by raising awareness of risks among our workforce, providing strong safety leadership and maintaining a commitment to continuously improving our process safety procedures, systems and standards.

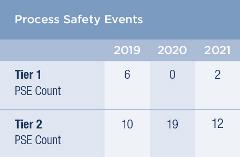

We experienced an increase in the number of Tier 1 PSEs in 2021 – with two incidents in 2021 compared with zero in 2020. On a longer term basis, however, we have reduced the number of Tier 1 PSEs by 60% between 2016 and 2021, based on our current portfolio of operated assets. We have completed investigations and root cause analyses of the Tier 1 PSEs that occurred in 2021 and are implementing appropriate corrective actions to help prevent similar incidents in the future.

compared with zero in 2020. On a longer term basis, however, we have reduced the number of Tier 1 PSEs by 60% between 2016 and 2021, based on our current portfolio of operated assets. We have completed investigations and root cause analyses of the Tier 1 PSEs that occurred in 2021 and are implementing appropriate corrective actions to help prevent similar incidents in the future.

Emergency Preparedness and Response

Hess’ emergency preparedness and response program is designed to respond to actual or potential injuries to people, spills and releases to the environment, damage to our assets and impacts to the company’s reputation – in that order of priority. We use a three tiered approach to plan for and respond to emergencies that integrates communication and action from the corporate level in Houston to asset and facility level response teams. This system helps ensure that standards, plans, information and resources work efficiently so that we understand and address the specific needs of the situation at hand.

Preparedness at Hess involves our emergency response organization, engagement with officials and communities, emergency facilities and response plans. We also maintain relationships with mutual aid and emergency response organizations at the local, regional and global levels.

Contractor Management

Contractors are critical to Hess, constituting approximately 65% of our total workforce hours and performing key tasks throughout our operations.

We use a recognized industry safety database to standardize our prequalification processes across multiple sites for our U.S. operations. This enables us to clearly communicate requirements and expectations to our contractors and share information efficiently.

The Hess Operational Management System addresses contractor capabilities and competencies, and we have implemented a Contractor Management Standard at our operated assets. For in scope contractors, our current standard includes requirements from initial sourcing to contracting to reviewing the work they do for us. As an extension of the Contractor Management Standard, in 2021, we implemented a new risk based contractor engagement process – which is at various stages of maturity at our assets – that requires certain engagement activities based on a contractor’s environment, health and safety (EHS) risk profile. The contractor engagement process also helps us prioritize engagement with higher risk contractors and focus our contractor management resources accordingly through a range of activities including management system reviews and performance assessments.

Our standard contract clauses include contractual obligations for our contractors to have safety requirements and programs that meet Hess’ expectations. We audit contractors through annual management system reviews, desktop reviews and field verification to confirm compliance with contract obligations; applicable Hess EHS requirements; contractor EHS requirements; local, state and federal requirements; and industry standards and best practices. In 2021, desktop reviews were conducted by third parties in place of in person interviews due to the COVID-19 pandemic.